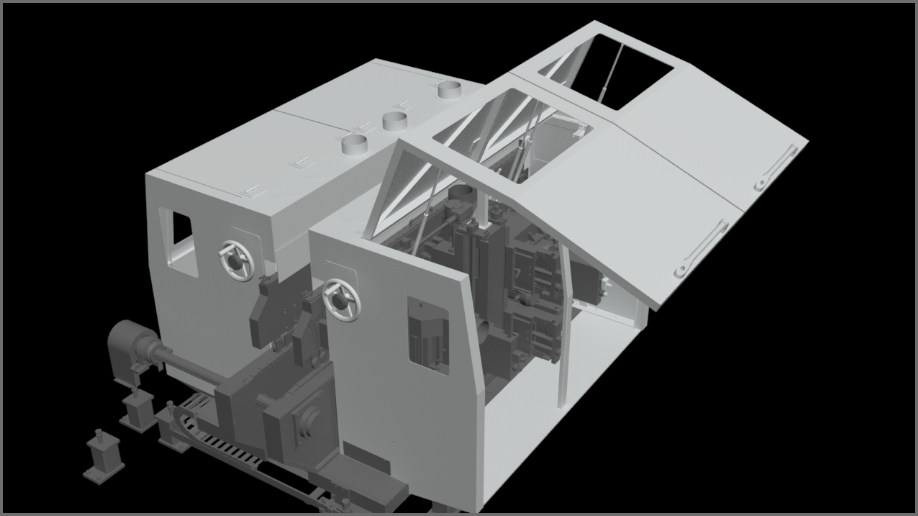

Yasuda's tenoners are fully designed and manufactured in-house. Skilled craftsmen thoroughly oversee quality control to ensure stable parts supply. We continuously upgrade stability and durability, supporting our products from our old machines to the new.

Yasuda offer fully customized tenoners designed to fit your production system, output, product specifications, and space availability. Our tailored machines enhance production capacity and solve common challenges. High-precision processing reduces failure rates and defective products, ensuring more stable operations.

Our tenoners are capable of processing various interior materials used in everyday living such as furniture, kitchens, exterior panels, flooring, counter tables, wall panels, doors, shelves, ceiling boards, staircases, and wooden partitions.

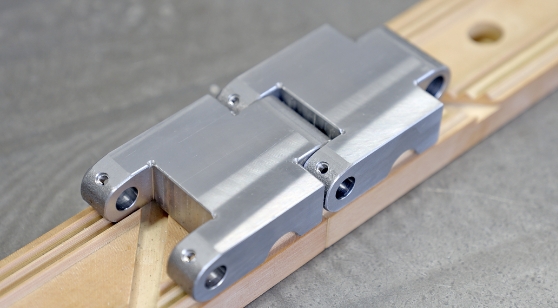

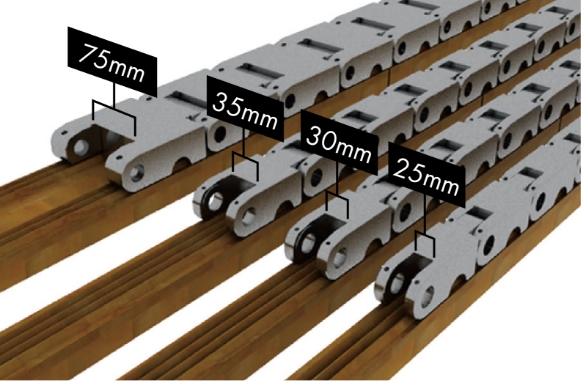

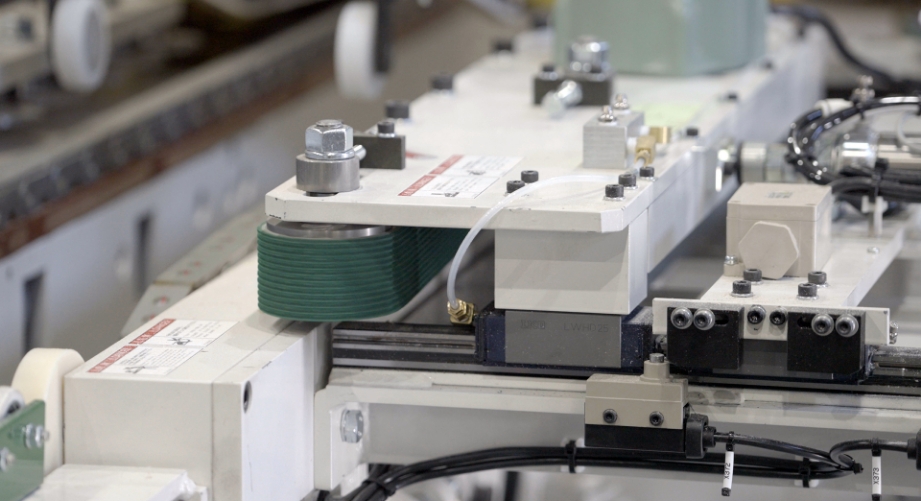

Yasuda’s strength lies in our wide variety of caterpillar chains, which are not available from other manufacturers. Achieves high-precision processing of workpieces wider than 75mm (milling only if 75mm in width).

Choose from chain widths of 75mm, 35mm, 30mm, or 25mm depending on your processing needs.

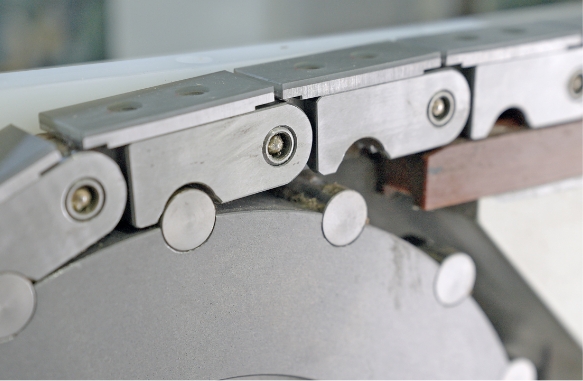

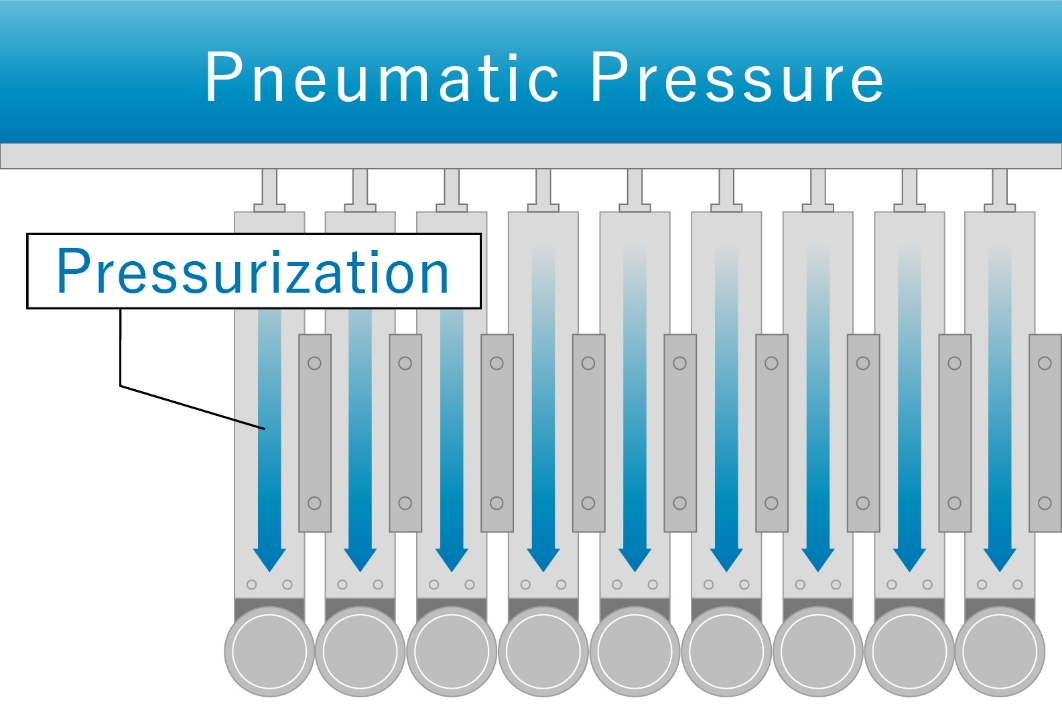

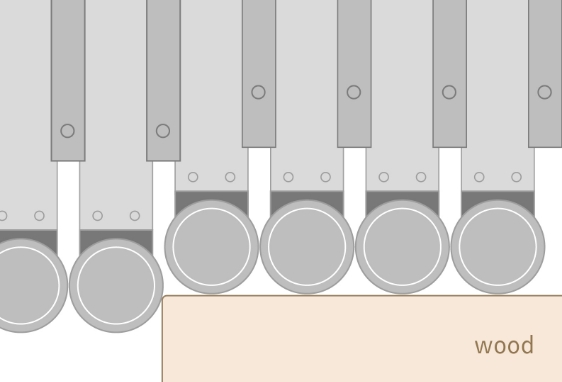

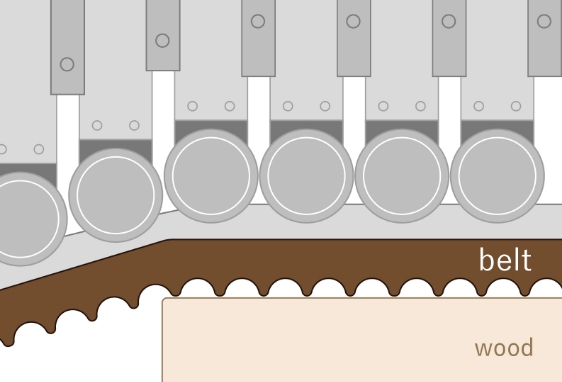

The air cushion system maintains stable pressure and hold-down margin. Pressure can be easily adjusted for various materials.

Ensures stable material feeding even at high speeds, allowing high-precision processing.

Firmly grips materials for precise processing of both long and short sides of workpieces.

We combine skilled craftsmanship with specialized equipment to achieve outstanding assembly precision. Experienced artisans meticulously control every process stage—from component fitting to final inspection under strict criteria that do not tolerate even the slight error—ensuring the highest standards of product quality.

We, Yasuda, specialize in designing and manufacturing custom-made machines that meet customer requirements. We excel in one-of-a-kind machine solutions that address production challenges, improve efficiency, and reduce labor. From initial planning to design, manufacturing, installation, and after-sales support—we offer full, end-to-end service.

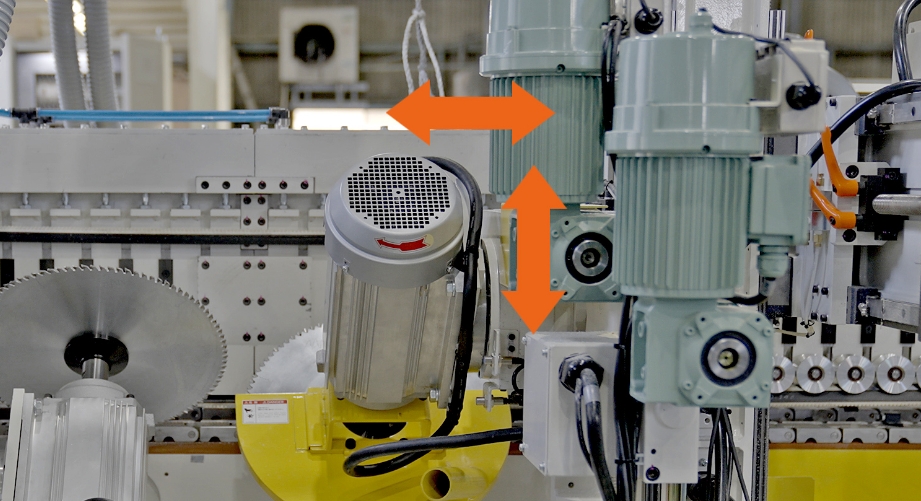

Automatically positions according to the material. Available in standard and high-speed types.

Insertion/discharge belts helps smooth workpiece feed.

The spindle position can be adjusted according to the material. Choose between automatic or manual adjustment via handle.

Equipping the machine with a cover not only enhances safety, but also reduces noise and prevents chip scattering. Cover equipment also improves the working environment and protects the machine for more comfortable and secure operation.

Supports stable material feeding by guiding it along the straightedge and enables consistent feeding during continuous line operations.

To ensure stable operation of your production line, we provide comprehensive in-house services—from machine design and manufacturing to repairs and complete overhauls. Our skilled technicians perform detailed inspections and maintenance to keep your machines in optimal condition.

We offer customized modification offers based on your needs. Our tenoners can be upgraded to enhance productivity and incorporate automation—flexibly adapting to evolving production demands.

There are many retailer throughout the country. Please contact us.

We serve customers not only in Japan, but also other countries such as China, South Korea, Vietnam, Indonesia, Malaysia, Taiwan, Thailand, other Southeast Asian countries, and Europe.

We serve customers within Japan.

We respond to the requests of customers all over the world. Please feel free to contact us.

TEL: +86-512-53231323

FAX: +86-512-53231323

TEL: +82-2-515-6671

FAX: +82-2-515-8209

TEL: +84-28-3517-3407

FAX: +84-28-3517-3402

TEL: +84-274-3618-639

FAX: +84-274-3618-638

Cells: +1-513-307-2794

TEL: +62 21 5637 676 / +62 21 5657 509

Feel free to reach out with any requests or

questions.

We also accept material requests and arrange

site visits.

The first step in machine development is to

understand your needs. We confirm the

purpose of the machine, specifications of the

parts to be produced, and any challenges.

Based on the initial hearing, we propose a

concept. This includes an outline and basic

specifications of your custom machine.

We create detailed designs based on the

proposal. This includes structure design,

component selection, and control system

planning.

Once the design is finalized, manufacturing

process starts. This stage includes machining

parts, assembly, and software installation.

After manufacturing, test runs are conducted.

We check operation, debugging, verify

processing precision and machine durability.

After test runs are complete, we conduct a

final inspection in the presence of the

customer to ensure all specifications are met.

When everything passes joint inspection, the

machine is delivered and installed at your site.

After installation, we conduct operational tests

and provide training on how to use the machine.